Ingenieur Büro Böhme

BLUECHIPS MICROHOUSE (EMS Service in Thailand)

Bluechips Microhouse is an international Electronic Manufacturing Service (EMS) provider based in Chiang Mai, Thailand. As an EMS company, the contract manufacturing service has to be able to offer cost-effective, efficient delivery of your electronic products, as well as offering the versatility required to benefit the customers across a wide range of end markets ranging from automotive, sensor, industrial, solar, medical and transportation industries.

Bluechips Microhouse can offer a one-stop solution to their customers, including product design, material procurement, mass production capabilities, quality control, testing, logistics and multi-lingual customer service.

Bluechips Microhouse is able to handle full projects as single supplier starting from research and development up to mass production. Whether your product is a simple PCBA or a complex full-product solution, the Bluechips Microhouse team is comfortable stepping in at any point.

Bluechips Microhouse has the quality in the centre of their production process, represented throw qualifications and accreditations; including ISO9001, ISO14001, ISO13485, SA8000 and official ESD certification IEC 61340 and ANSI S20.20.

Bluechips Microhouse facility has 2400qm of production space and 600qm climate-controlled warehouse. Area and state-of-the-art machinery make sure that your products are produced on schedule and defect free. Our production floor is laid out to allow the material to flow smoothly from our warehouse to our production lines and onwards to the packing and shipping area.

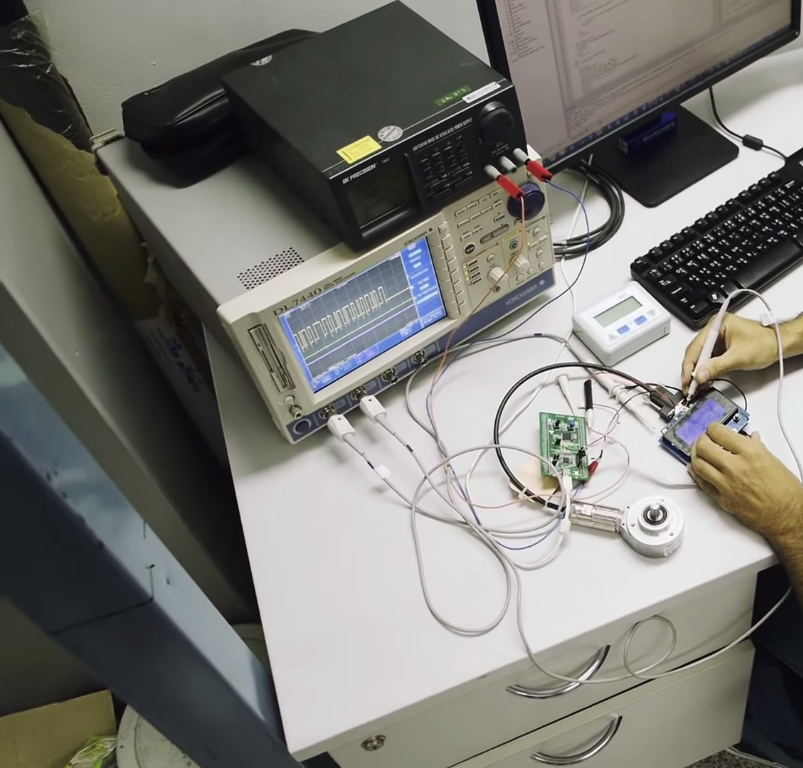

Bluechips Microhouse growing team, new lines being added to our production floor and investments being made in test equipment, as well as our ongoing emphasis on communication and cooperation, makes it exciting and easy to start working with.

Production

Bluechips Microhouse is capable to offer a lot of services for a wide range of companies and products. The state-of-the-art production floor makes it possible.

⇒ PCB Assembly – SMT, COB & IMT

⇒ 5 SMT Lines; including a new Fuji NXT111C line

⇒ Wave Soldering, including Full Tunnel Nitrogen Double Wave Solder Machine & selective soldering

⇒ Vapour Phase Soldering

⇒ Multiple Reflow Ovens

⇒ Die Bonding Capabilities

⇒ Resin Potting

⇒ Trumpf Laser Marking and Screen Printing Capability

⇒ AOI (x3), X-ray and ICT Testing Machinery

⇒ Stencil & PCBA Cleaning Machines

⇒ Cable and Harness Assembly

⇒ CNC Milling, Metalwork and Laser Welding

⇒ Ultrasonic Welding via Branson machinery

Research & Development

Bluechips Microhouse offers full-product solutions to our customers, a lot of emphasis is placed on the R&D department. This is possible through significant investment.

⇒ New product designs & concepts

⇒ Capabilities of designing firmware, hardware and embedded software.

⇒ Circuit & PCB design

⇒ EMC Design and testing

⇒ A smooth transition into mass production via our New Product Introduction department.

⇒ Technical support from our multi-national team in English, German, Italian, Thai, Russian and more.

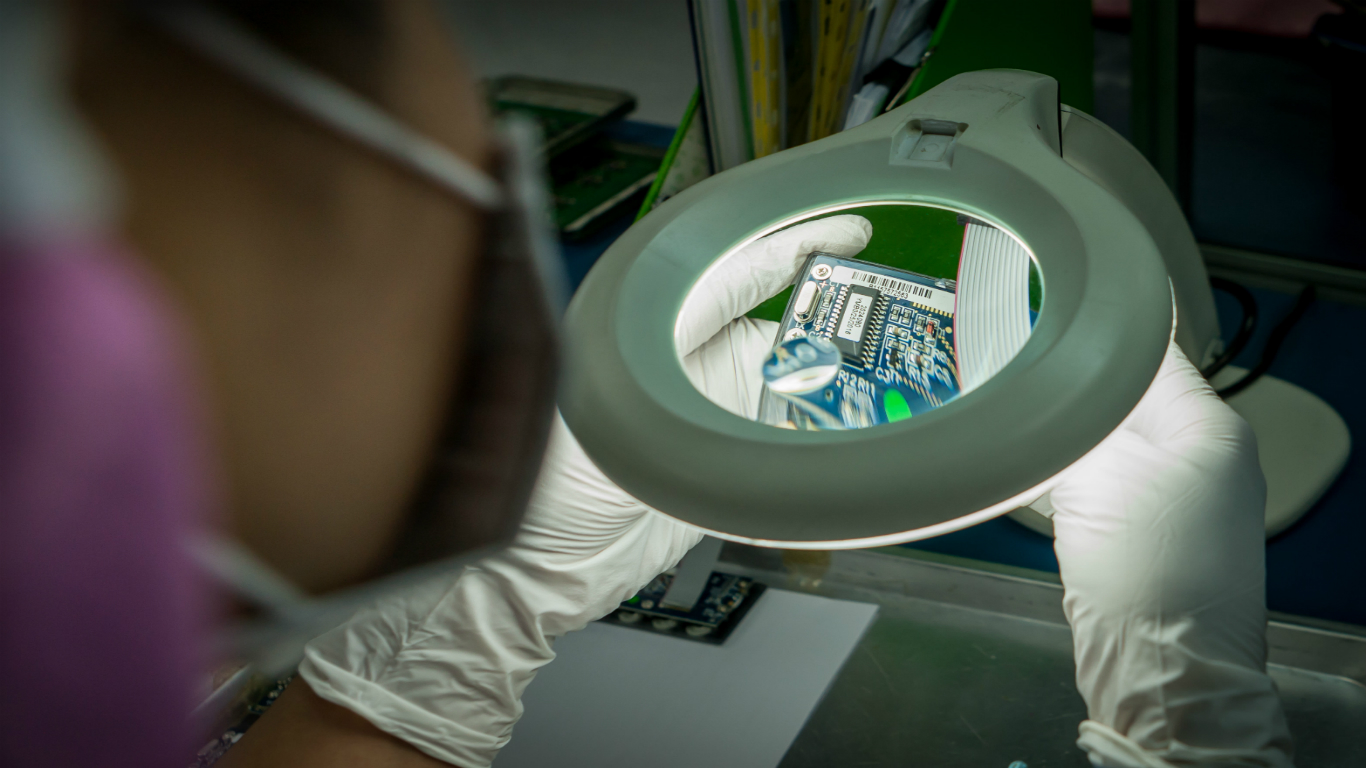

QUALITY ASSURANCE

Bluechips Microhouse do automatic inspection as well as manual quality control to guarantee the highest possible quality in the production.

Testing Possibilities

⇒ AOI -> Viscom S3088 Basic x2 -> 2.5D

⇒ AOI -> Viscom S3088 Altra -> 3D

⇒ X-ray -> Dage DX7500NT

⇒ SPI -> Solder Paste Inspection

⇒ In-Circuit Testing including boundary scan and functional tests

Sigma MTS300 machine x2

Dedicated ICT tester

Functional Testing Options:

⇒ Test equipment supplied by customer

⇒ Test equipment developed according to customer specifications based on LabVIEW soft/hardware

Location

⇒ Bluechips Microhouse, Lamphun, Thailand

⇒ Bluechips Microhouse, Chiang Mai, Thailand

Please call me (+49 172 3830507) or send an email (bluechips@elektronikcad.de).